Developing a secure, on-premise web application to automate gauge tracking, calibration scheduling, and compliance management for manufacturing operations.

GuageWise

GuageWise

Before GaugeWise, the client’s gauge tracking and calibration management relied heavily on manual Excel sheets distributed across multiple departments.

This approach led to several critical issues:

Data Inconsistency and Errors:

Manual entries made it difficult to maintain accurate records of gauge usage, calibration status, and assignment history, increasing the risk of operational mistakes.Lack of Real-Time Visibility

Teams had no immediate way to check which gauges were available, assigned, under calibration, or overdue, slowing down internal workflows and decision-making.Calibration Compliance Risks

Missed calibration deadlines could directly impact product quality and compliance with ISO and customer audit requirements, creating serious reputational and financial risks.Inefficient Reporting and Traceability

Preparing reports for audits or internal reviews was time-consuming, error-prone, and lacked a centralized system to generate reliable calibration certificates or history logs.Need for Secure, On-Premise Deployment

Due to strict internal IT security policies, the solution had to be hosted entirely on the client’s infrastructure, ensuring full data control without any external dependencies.Centralized Gauge Tracking Platform

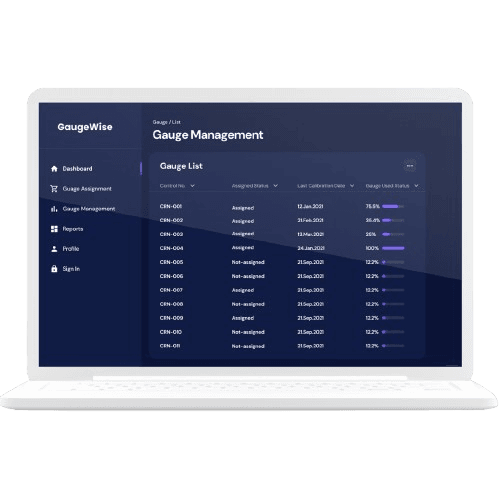

We developed a web-based dashboard where gauge room managers could easily track gauge assignments, returns, and calibration history in real-time, with role-based access control for enhanced security.Data Migration and Cleanup

A custom migration module was built to transfer legacy Excel data into the new system. It validated, cleaned, and structured historical records, ensuring accurate and reliable database initialization.Automated Calibration Scheduling & Alerts

The system generates automated reminders for upcoming calibrations and sends email notifications for overdue items, reducing the risk of non-compliance and improving equipment reliability.Secure On-Premise Hosting

GaugeWise was deployed on the client’s internal servers, ensuring complete data security, compliance with internal IT policies, and full control over system operations.Enhanced Reporting and Insights

Custom reporting features allow teams to generate calibration certificates, audit trails, and Measurement System Analysis (MSA) reports, providing deeper operational visibility and compliance readiness.95% Reduction in Manual Data Efforts

By eliminating spreadsheet tracking, GaugeWise significantly reduced manual workloads, minimizing human error and saving valuable operational time.

Faster and Smarter Gauge Management

Real-time visibility into gauge locations, calibration schedules, and maintenance history helped teams make quicker, more informed decisions and optimize internal workflows.

Improved Compliance and Product Quality

With automated calibration tracking and instant access to historical documentation, the company achieved zero missed calibrations, improving product quality and audit preparedness.

Take a look at how we've partnered with businesses to build impactful digital solutions-each project tailored to unique goals, challenges, and industries.

We’ll get back to you within 24 hours.