Developing a smart, on-premise web application to automate tool tracking, optimize tool consumption, and integrate shop floor tool management with enterprise systems.

Tool-IT

Tool-IT

Before implementing Tool-IT, the client faced multiple operational inefficiencies:

Manual Tool Tracking:

Tool issuance and return were manually logged, leading to frequent errors, unauthorized tool use, and high tool loss.Hidden Machining Costs

Without real-time visibility, the company had no accurate way to allocate tool consumption costs to specific machines or production orders.Operational Downtime

Misplaced or inappropriate tool assignments caused unexpected machine downtime and tool breakages.Lack of Centralized Data

Manual systems made it difficult to audit tool usage, monitor procurement needs, or analyze operational inefficiencies.Need for On-Premise Security

Data security requirements demanded an on-premise solution that integrated with the company’s existing SAP ERP infrastructure.RFID and Biometric-Enabled Tool Tracking

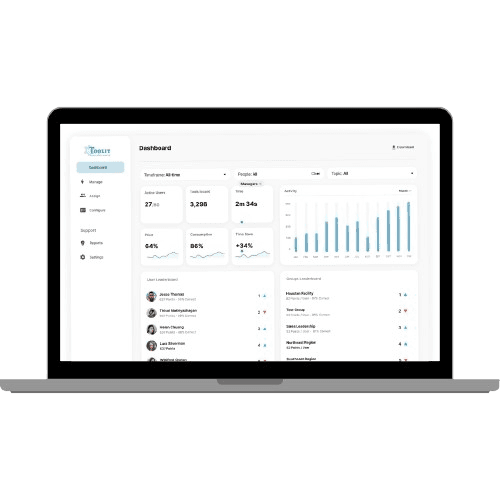

Floatinity developed a system that uses RFID tags and fingerprint authentication for tool issuance and returns. Tool crib managers can assign tools instantly with a scan, eliminating manual logging errors and unauthorized access.Real-Time Visibility and Smart Insights

Tool-IT provides real-time dashboards displaying tool usage, machine-wise allocation, and consumption patterns. This visibility helps in minimizing losses and improving tool lifecycle management.Cost Optimization and Procurement Control

By ensuring correct tool selection and preventing inappropriate use, Tool-IT reduced tool wear, breakage, and unnecessary purchases—leading to significant savings in tool consumption costs.Seamless SAP ERP Integration

Tool-IT was integrated with the client’s SAP ERP system to automate real-time cost allocation, link tool consumption with production orders, and streamline procurement planning based on accurate tool usage data.Paperless, Audit-Ready Documentation

The system shifted tool management operations from paper-based logs to a fully digital workflow, ensuring 100% paperless transactions and providing audit-ready reports for internal and external compliance needs.20% Reduction in Tool Consumption Costs

By improving tool selection accuracy and minimizing waste, Tool-IT directly contributed to cost savings and better resource planning.

80% Reduction in Tool Losses

RFID and fingerprint-based tracking drastically reduced misplaced tools, improving operational reliability and machine uptime.

40% Time Savings in Tool Management

Automating tool assignment, returns, and reporting allowed floor managers to focus on production, reducing administrative workload and speeding up daily operations.

Take a look at how we've partnered with businesses to build impactful digital solutions-each project tailored to unique goals, challenges, and industries.

We’ll get back to you within 24 hours.